Reliable and Experienced Manufacturing

Aerospace applications retail extreme attention to detail, and there is no room for error. Our team has over 80 years of experience turning innovative designs into unparalleled and reliable products that can stand up to the toughest environments.

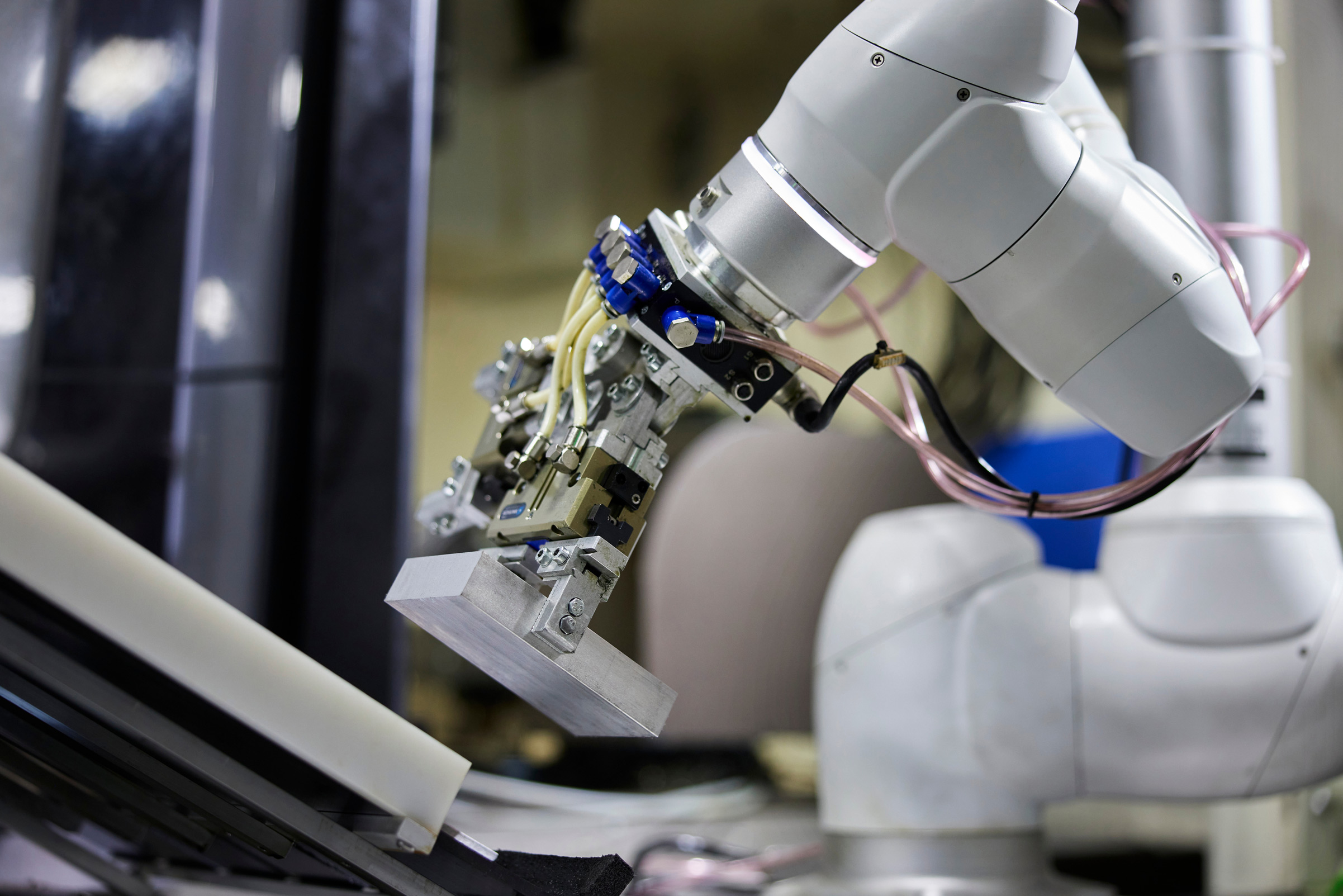

Sophisticated Machining

We are experts in complex machining with precise tolerances for a broad range of aerospace applications. Our state-of-the-art machining capabilities, coupled with advanced technology, enable us to create complex aerospace components with utmost accuracy and consistency.

Precision Assembly

We employ advanced assembly techniques and highly trained personnel who meticulously piece together each component. Every step of the assembly process is carefully monitored and tested, guaranteeing the quality and integrity of our aerospace solutions.

.jpg)

Cost Efficient

By embracing cost-effective practices without compromising quality, we can offer our customers cost-efficient aerospace products that meet their value-conscious needs without sacrificing performance or safety.

PRECISION MACHINING

Precision Machining

LEAN MANUFACTURING PRACTICES

Lean Manufacturing Practices

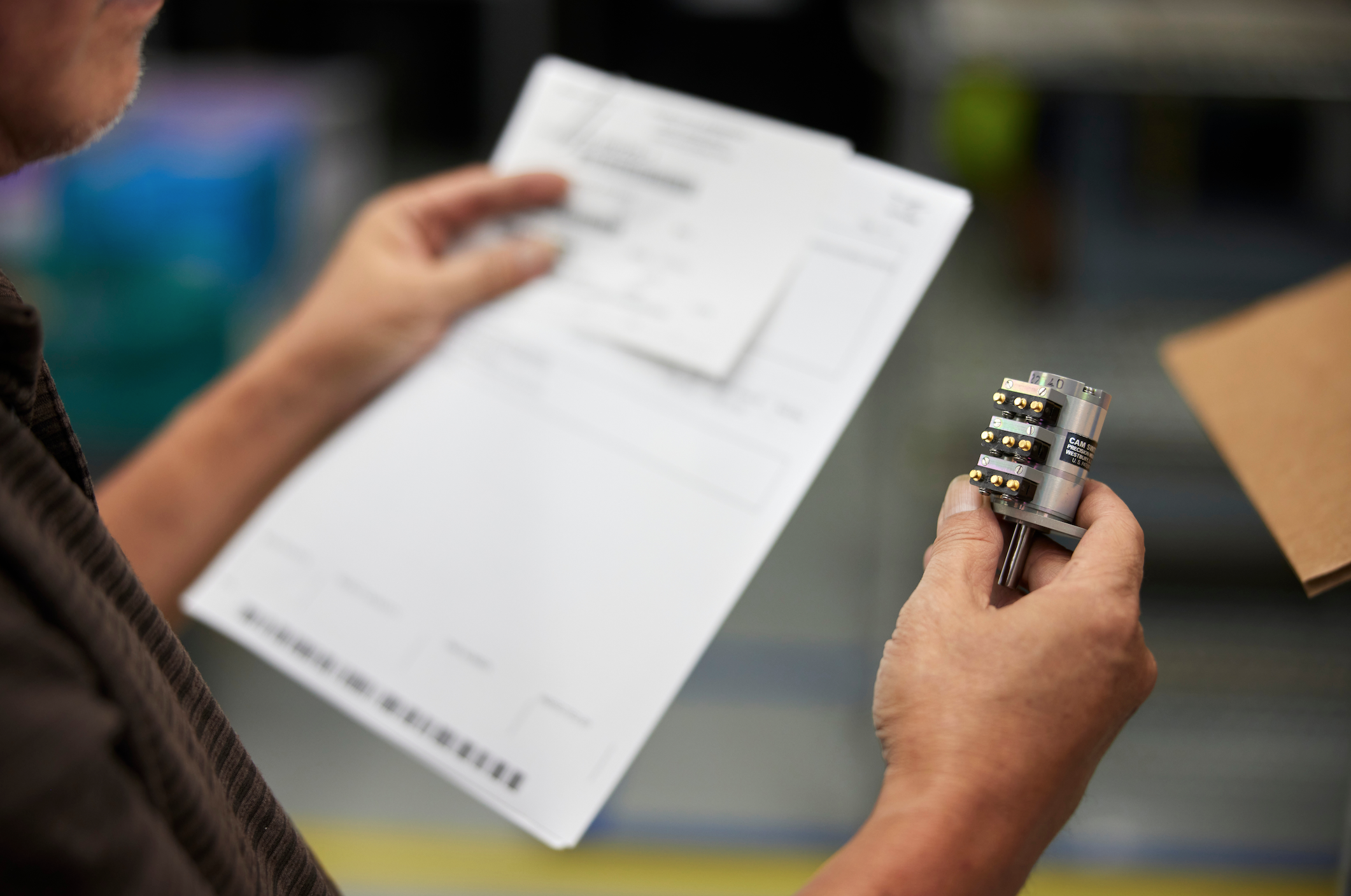

QUALITY CONTROL & ASSURANCE

Quality Control and Assurance

Quality control is at the heart of our manufacturing process. We implement rigorous quality assurance measures, including thorough inspections and testing, to guarantee that our products meet and exceed aerospace industry standards.

JUST-IN-TIME MANUFACTURING

Just-in-Time Manufacturing

Just-in-time manufacturing strategies minimize inventory costs and increase responsiveness. This method allows us to provide customers with products precisely when they are needed, reducing lead times and resource waste.

SKILLED WORKFORCE & TRAINING

Skilled Workforce and Training

ADVANCED MATERIALS & COMPOSITES

Advanced Materials and Composites

ADVANCED ADDITIVE MANUFACTURING

Advanced Additive Manufacturing

We leverage cutting-edge additive manufacturing techniques, including 3D printing and additive layer manufacturing. These advanced processes enable us to create complex and lightweight aerospace components with exceptional precision and efficiency.

ENVIRONMENTAL SUSTAINABILITY

Environmental Sustainability

Adams Rite Aerospace is committed to environmentally responsible manufacturing. We implement sustainable practices to reduce our environmental footprint, from eco-friendly material choices to energy-efficient production methods.