Meeting Customer Requirements & Expectations Every Time

The job isn’t finished when your product is designed. At Adams Rite, our commitment to product performance is unwavering, as we utilize an in-house testing laboratory to ensure that our products perform exactly how they were designed to. That’s how we exceed your expectations every step of the way.

Invested in Testing Quality

We've made substantial investments in a wide range of testing systems, including those for Tensile, Compression, Flexure and Peel tests. Additionally, we house a state-of-the-art Halt Chamber for accelerated testing. Our in-house expertise extends to the development of endurance and functional testers, among many other testing solutions.

3D Printing

We leverage cutting-edge 3D printing technology as an integral part of our testing processes. This innovative approach allows us to create intricate prototypes and components swiftly, enabling us to conduct rigorous tests with precision and efficiency.

Life Cycle Testing

Our life cycle testing method involves subjecting our products to a series of rigorous tests that simulate real-world conditions and operational stressors, such as temperature variations, mechanical loads and environmental factors. By conducting extensive life cycle testing, we can accurately assess the durability and performance of our components over their entire service life.

HALT & ESS TESTING

Halt & ESS Testing

DECOMPRESSION TESTING

Decompression Testing

Our decompression testing is essential for simulating the extreme conditions of high altitudes. This testing helps us ensure that our aerospace solutions maintain their functionality and structural integrity in the most demanding conditions.

CORROSION TESTING

Corrosion Testing

Corrosion testing is an integral part of our process, allowing us to evaluate how our products resist corrosion and deterioration over time.

TEMP & HUMIDITY TESTING

Temp & Humidity Testing

This testing allows us to replicate a wide range of environmental conditions, from extreme cold to scorching heat and varying humidity levels.

FATIGUE TESTER

Fatigue Tester

Our fatigue testers put our products through cyclic loads and stresses, replicating the conditions they may encounter during their service life.

FLUID SUSCEPTIBILITY TESTING

Fluid Susceptibility Testing

Fluid susceptibility exposes our products to a range of fluids, including fuels, hydraulic fluids and chemicals, to assess their resistance and compatibility.

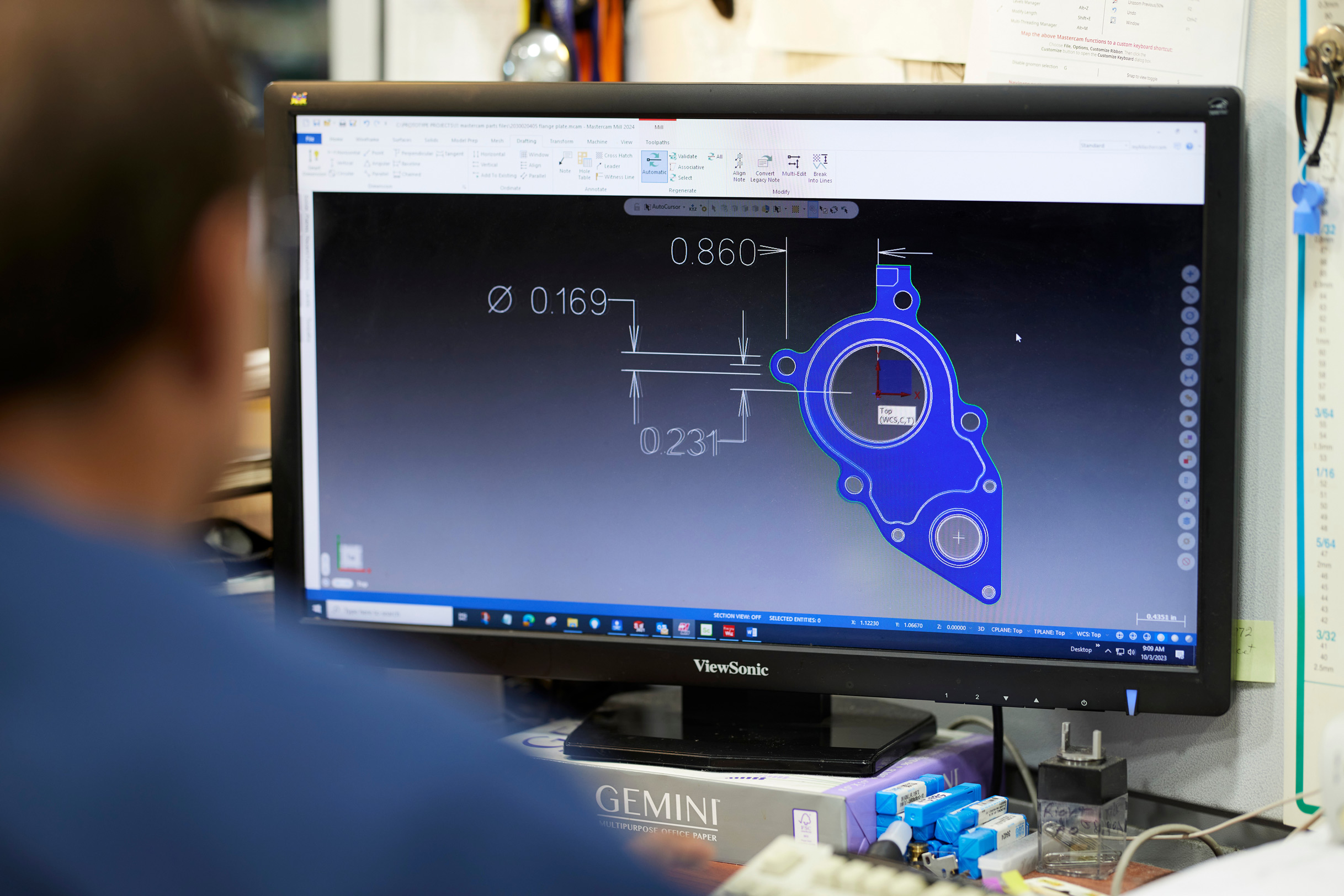

3D DESIGN TECHNOLOGY

3D Design Technology

We utilize state-of-the-art computer-aided 3D design (CAD) software to rigorously test and refine our product designs. It enables us to create detailed 3D models, allowing us to simulate real-world conditions and performance scenarios.

DATA ACQUISITION SOFTWARE

Data Acquisition Software

Our data acquisition software allows us to efficiently collect and analyze critical data during the testing process. With its user-friendly interface and powerful data acquisition capabilities, we can monitor various parameters, such as temperature, pressure and electrical signals, in real time.